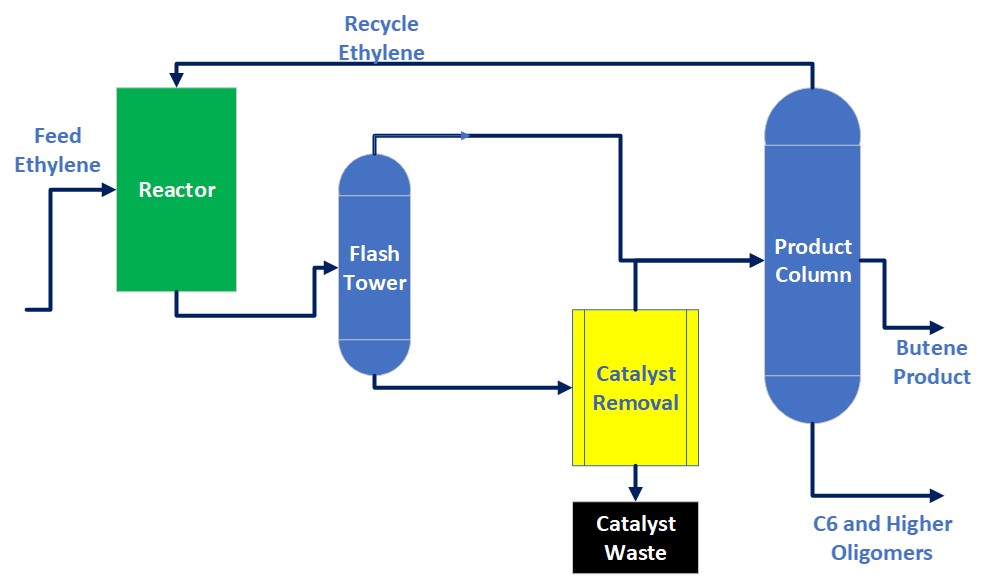

The ButeneSynth™ Process is a state-of-the-art process for the synthesis of high purity 1-butene. Utilizing the dimerization of ethylene, this process achieves remarkable conversions and selectivity. Central to its success is a uniquely engineered reactor system that ensures optimal mixing, thus promoting the desired chemical reactions. Complementing this sophisticated reactor is our proprietary catalyst system, meticulously developed through extensive research and innovation. The final product boasts an exceptional purity level exceeding 99.2%, rendering it ideal as a comonomer in the production of premium-grade Linear Low-Density Polyethylene (LLDPE) and High-Density Polyethylene (HDPE).

Visonics Chemicals proudly presents our cutting-edge Reagent Purification Technology (RPT™), specifically designed to address the challenges posed by trace oxygenates in reagents. These trace oxygenates can lead to catalyst deactivation and reduced performance.

Our revolutionary technology delivers an efficient and cost-effective solution for removing trace oxygenates from reagents, ensuring the optimal functionality of additive components without affecting catalyst activity.

We have successfully purified a series of reagents with varying viscosities for a recent customer using our proprietary column materials. To guarantee the highest quality standards, we employed Karl-Fisher tests and dew point testers to confirm moisture levels below 50 ppm and free oxygen levels in sub-ppm quantities.

By choosing Visonics Chemicals’ Reagent Purification Technology (RPT™), you can achieve unparalleled catalyst performance and unleash the full potential of your reagents, enhancing the efficiency and effectiveness of your processes.

Visonics specializes in providing tailored advice and services on hazardous waste disposal to address each client’s unique needs. Hazardous waste could be reclassified as non-hazardous (non-flammable, non-corrosive, non-toxic, and neutralized) by using Visonics services.

Visonics RWT technology can be employed to convert metal-containing hazardous wastes (flammable and pyrophoric). Aspects of the technology include precipitating the hazardous metal complexes out to achieve compliance in both pyrophoricity and pH values. As a result, both the liquid and solid can be disposed of as non-hazardous waste. Alternatively, RWT technology allows for the liquid portion to be re-used as a waste disposal agent or a process solvent.

At Visonics Chemicals, our dedicated team of experienced chemists and engineers are committed …

Copyright © 2023 Visonics Chemicals. All rights reserved.