At Visonics Chemicals, we offer comprehensive consultation services to identify the root causes of industrial challenges and provide effective solutions using our technologies and beyond. Our in-house expertise encompasses organic chemistry synthesis, characterization, chemical engineering process design, and scale-up, positioning us as your ideal partner for tackling any challenge.

Trust Visonics Chemicals for Your Advanced FEA Needs

Trust Visonics Chemicals for Your Advanced FEA Needs

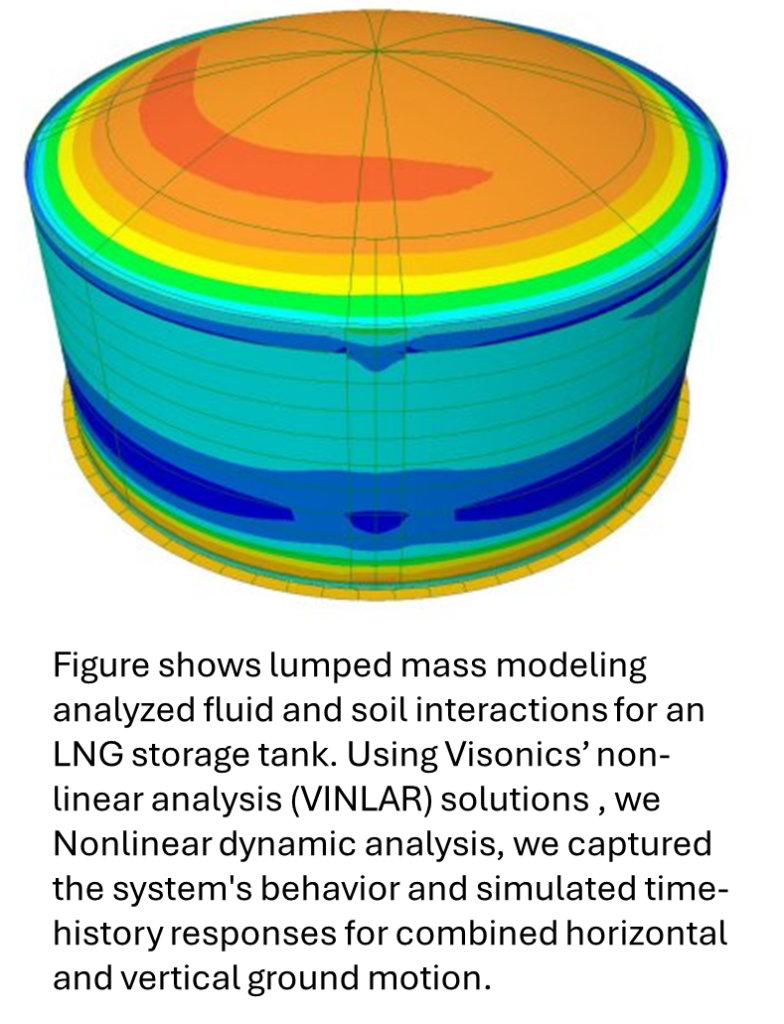

Visonics Chemicals offers advanced Finite Element Analysis (FEA) for storage tanks, a powerful method for ensuring safety and structural integrity under various conditions. FEA allows for precise simulations of stress scenarios, including seismic activity, pressure changes, and thermal effects. This analysis helps identify potential weaknesses and optimize process equipment and tank design.

Data-Driven Approach to Pressure Vessel and Tank Analysis

We start with detailed 3D laser scanning, capturing the exact geometry of each tank. This data forms a high-resolution model, which is then used in FEA software to simulate real-world stressors. These simulations provide insights into deformation, stress distributions, and potential failure points.

Benefits of Our FEA Services

Why Choose Visonics Chemicals?

Our FEA services provide reliable, accurate analysis, helping you optimize safety and performance while maintaining cost efficiency. Trust Visonics Chemicals to enhance your storage infrastructure with data-driven precision with our customized VINLAR solutions.

Trust Visonics Chemicals for your high throughput experimentation (HTE) needs. HTE is a powerful methodology that allows for the rapid screening and testing of numerous samples in a short timeframe. Widely employed in materials science, chemistry, and engineering, HTE expedites the discovery, development, and optimization of novel materials, catalysts, and chemical processes.

Trust Visonics Chemicals for your high throughput experimentation (HTE) needs. HTE is a powerful methodology that allows for the rapid screening and testing of numerous samples in a short timeframe. Widely employed in materials science, chemistry, and engineering, HTE expedites the discovery, development, and optimization of novel materials, catalysts, and chemical processes.

In homogeneous catalysis, Visonics swiftly leverages HTE tools to pinpoint the most active catalysts and ideal reaction conditions, such as temperature, pressure, and solvent, for a specific reaction. By screening a vast array of catalysts and conditions, researchers can identify the most promising candidates for further optimization and scale-up.

In heterogeneous catalysis, Visonics utilizes HTE tools to rapidly assess a multitude of catalysts and support materials, identifying the most active and selective catalysts for a particular reaction. Our unique systems also assist in optimizing catalyst preparation and synthesis, including particle size, shape, and composition, factors that can substantially impact catalytic performance.

Visonics is committed to being your ally and advocate in catalysis and additives research, technology development, and eventual scale-up and commercialization. Our team is adept at quickly identifying the most promising candidates for further development and optimization. This streamlined approach reduces the time and resources typically required for traditional trial-and-error methods, which can be both costly and time-consuming.

At Visonics, we specialize in providing toll manufacturing services for the fine chemicals, oil & gas, and petrochemical industries. As a key aspect of our business, we have extensive experience in working with companies to produce products that meet their exact specifications and expectations.

Our comprehensive range of services is designed to assist customers in delivering their products to the market efficiently and effectively. Among the services we offer are

Turn-key Tolling: Visonics manages the entire process, from purchasing raw materials to manufacturing, testing, packaging, and shipping the final product on behalf of our customers.

Specialty Catalysts and Additives: We can also provide custom catalysts or additives for your unique manufacturing needs.

With our commitment to quality and customer satisfaction, Visonics is the ideal partner for your toll manufacturing requirements. Please do not hesitate to contact us if you have a tolling opportunity or if you are in search of a specialty catalyst or additive.

At Visonics Chemicals, our dedicated team of experienced chemists and engineers are committed …

Copyright © 2023 Visonics Chemicals. All rights reserved.